Even small incremental adjustments can result in time-consuming workarounds. When having to meet strict tolerance requirements it’s often necessary to have to offset the position of a toolpath in relation to the model geometry. Now, you can send an offset to feed in from a specific distance and drill to a specific position regardless of features size eliminating the need to create any extra construction geometry. For example, new options to control hole start and end position provide much greater flexibility when you are defining drilling operations. SOLIDWORKS CAM 2019 also adds great productivity enhancements for creating everyday machining operations. By using this machine in combination with SOLIDWORKS CAM’s automatic feature recognition, an optimized set of operations will be automatically generated. After switching to view the properties of the 4-axis machine tool, the 4-axis rotary strategy can be chosen as its default machining strategy.

Solidworks 2019 cam update#

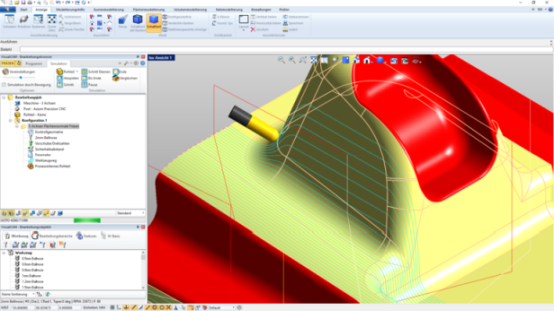

We’ll go ahead and make a couple of changes by setting the rectangular corner slot and circular boss to use rough finish edge break operations then saving to update the overall strategy set. Selecting the 4-axis rotary set displays the list of its unique features and operations. Three different sets of machining strategies have already been predefined in the database, including one for a 4-axis rotary table. The remaining features of my camera mount are going to be machined using a 4-axis rotary table. The technology database now provides you with the option to define multiple machining strategies and assign them to a specific machine. NC programmers using multiple machine tools can now take even greater advantage of SOLIDWORKS CAM ’s powerful automation capabilities. By enabling corner slow down, you can now vary the feed rate based on distance resulting in increased tool life and improved surface finish. Corner slow down optionĪnother great enhancement for SOLIDWORKS CAM 2019 is the addition of the new corner slow down option. As sizes are inputted the preview of the tool updates in the graphics area showing the new tool and holder shape in relation to the part so you can now predict the final result with even greater accuracy. For this operation, we’ll change the type to neck then specify the size of first the tool neck followed by the tool holder. SOLIDWORKS CAM 2019 adds new taper and neck options for the noncutting portion of a tool. As the straight tool gets to the bottom of the part, there’s a risk that the shank will touch some of the faces at the top that were already machined earlier in the operation, spoiling the surface finish. To finish programming the camera mount, we’re going to make some changes to the contour milling operations for the outer faces. Switching configurations to set up one reorientates the part and changes the operations tree to display only the operations you need to the setup. Two configurations, each containing their own unique set of manufacturing operations have been defined in order to machine the front and rear flanges of this camera mount part. Learn more about configurations and a slew of other new enhancements that can help you improve quality and reduce the time required to generate NC programs. Configurations in SOLIDWORKS CAM 2019 is a great time saver that enables you to define multiple manufacturing setups within a single part or assembly. SOLIDWORKS 2019 delivers some great new CAM milling features that will help you reduce the time it takes to program your parts.

0 kommentar(er)

0 kommentar(er)